Home > Blog detail

Jul 2024

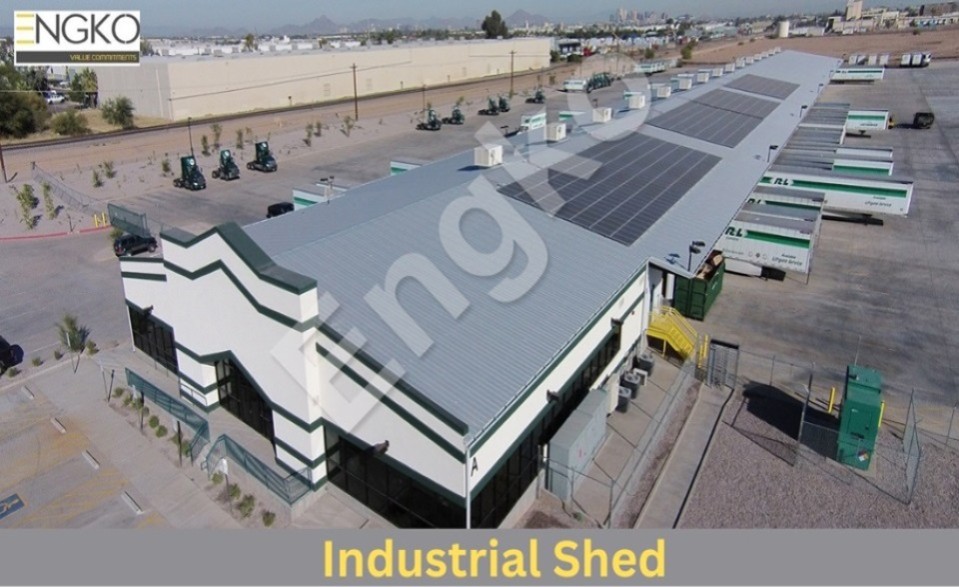

ENGKO, a leading manufacturer of prefabricated structures, provides high-quality pre-engineered industrial shed manufacturers at standard construction costs. It has become the fastest-growing supplier and manufacturer of industrial shed in India, catering to the diverse demands of the construction industry.

The demands of construction sites are increasing rapidly as civil construction reaches new heights. To meet these requirements, there is a high demand for prefabricated industrial shed. These sheds are preferred due to their cost-effectiveness and the fact that they can be quickly installed and disassembled.

The need for robust, cost-effective, and efficient solutions is paramount in the dynamic realm of industrial infrastructure. ENGKO, a leading player in industrial construction, has emerged as a game-changer with its state-of-the-art industrial sheds. Prefabricated structures are designed to meet the evolving demands of modern industries, offering a perfect blend of durability, versatility, and sustainability.

ENGKO's industrial shed are a testament to cutting-edge design and engineering. The structures are meticulously crafted to accommodate diverse industrial applications, providing a versatile space that can be tailored to specific requirements. The company employs advanced design software and engineering techniques to ensure structural integrity and optimal space utilization.

One of the standout features of industrial shed is their adaptability to a multitude of industries. Whether it's manufacturing, logistics, warehousing, or any other industrial activity, these sheds can be customized to suit the unique needs of each sector. Engko understands that every industry has its distinct challenges, and its sheds are engineered to address these challenges effectively.

ENGKO places a premium on the quality of materials used in the construction of its industrial sheds. These structures are built to withstand harsh weather conditions, heavy loads, and other environmental factors. The use of high-quality steel and advanced construction techniques ensures the longevity of the sheds, providing businesses with a sound and durable infrastructure for their operations.

In an era where sustainability is a key consideration for businesses, ENGKO's industrial sheds are designed with energy efficiency in mind. These structures can be equipped with energy-efficient lighting, insulation, and ventilation systems, contributing to a greener and more sustainable industrial landscape. ENGKO is committed to reducing the carbon footprint of its constructions, aligning with global efforts towards environmental conservation.

It understands the importance of time in the industrial sector. With their innovative construction methods and modular designs, the company ensures a quick turnaround time for the installation of industrial sheds. This not only minimizes downtime for businesses but also allows them to start operations swiftly.

Adhering to international standards and safety regulations is non-negotiable in industrial construction. ENGKO's industrial sheds are built with a focus on compliance and safety. The company prioritizes the well-being of workers and the security of industrial assets, ensuring that the structures meet or exceed the required safety standards.

Our top priority at ENGKO, the leading industrial shed manufacturers company in India, is to provide custom-designed architecture and client-specific construction for prefabricated structures. We believe that meeting the exact requirements of our customers forms the cornerstone of our progress and success. Our pre-engineered fabricated structures are made of high-quality raw materials and undergo a detailed manufacturing process, ensuring a lifetime guarantee of durability and optimum service. Here are some of the key features of these structures:

· Robust construction with durable materials for long-term stability.

· Designed to withstand heavy loads and adverse weather conditions.

· Ample space for storage, manufacturing processes, or other industrial activities.

· Installation of fire prevention and suppression systems.

· Efficient use of materials and construction methods to control costs.

· Implementation of eco-friendly practices and materials where possible.

· Design considerations for energy efficiency and waste reduction.

Wall: Insulated sandwich panels with PPGI sheet on both sides made of PUF / EPS at 50 / 60mm thickness.

Roof: Choose from PUF/EPS insulated sandwich panels with a thickness of 30/40mm or PPGI roofing sheets.

Doors: We will provide insulated doors along with all necessary accessories from our manufacturing setup.

Windows: We will provide aluminum anodized sliding windows from our manufacturing setup

Structure and Accessories: All necessary supporting accessories and structures will be provided before the project delivery.

ENGKO, the leading manufacturer and supplier of industrial shed in India, uses high-grade materials and a complex production process to gain an edge over its competitors. The company's main goal is to provide products that meet the specific needs of its customers. ENGKO's prefabricated industrial sheds offer several advantages over other options, including:

Q: What is an industrial shed?

A: An industrial shed is a large structure typically used for storage, manufacturing, or other industrial purposes. These sheds are usually made from steel or other durable materials and are designed to provide a spacious, open area for various industrial activities.

Q: What are the typical uses of an industrial shed?

A: Industrial sheds are used for a variety of purposes, including warehousing, manufacturing, workshops, storage of goods and machinery, agricultural purposes, and even as distribution centers.

Q: What materials are used to construct an industrial shed?

A: Industrial sheds are commonly constructed using steel frames, metal cladding, and sometimes concrete. The choice of materials depends on the intended use, budget, and environmental conditions.

Q: How long does it take to construct an industrial shed?

A: The construction time varies depending on the size and complexity of the shed. Typically, it can take anywhere from a few weeks to several months.

Q: What factors influence the cost of an industrial shed?

A: Several factors influence the cost, including the size of the shed, materials used, design complexity, location, and any additional features or customizations.

Warehouse Manufacturers

Factory Buildings

Pre-engineered Buildings

Prefabricated Site Office

Terminal Buildings

Call

: +91-9667986005